Stranded vs. Solid Wire: Optimal Choice and Reasons

Wires are vital channels in electrical systems, allowing electric current to flow effortlessly. Stranded and solid wires are two distinct kinds and the choice between them is crucial for guaranteeing the system's optimal performance. This blog will guide you through choosing between solid and stranded wires. We will consider factors like flexibility, routing, protection, distance, cost, and current carrying capacity to ensure an easy way to make choices between stranded wire and solid wire.

What is Stranded Wire?

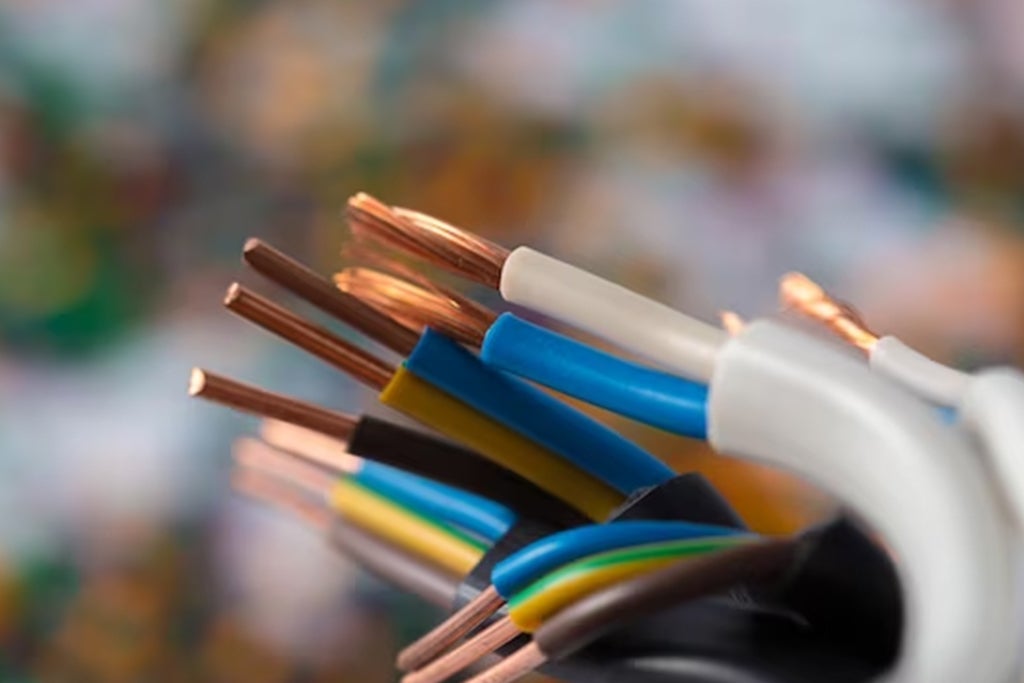

Stranded wire, used in electrical applications, comprises multiple twisted or braided metal strands, enhancing flexibility compared to solid wire. Commonly made of copper or aluminium, it is ideal for situations requiring frequent bending or movement. This versatility makes stranded wire essential in power cables, speaker wires, and other applications demanding flexibility and durability

How is Stranded Copper Wire Made?

Stranded or bunched copper cable is formed by twisting various smaller gauge wires together to produce a larger gauge wire. Different stages are involved in the production of stranded copper that include drawing as well as annealing individual wires and then, these are twisted around a central wire with the help of a machine.

Advantages of Stranded Wire

- Flexibility: Stranded wires are more flexible which makes them a perfect choice in situations where the wires need to bend or twist. This feature makes it easier to run through pipes and conduits in walls.

- Current Flow: Air gaps between the strands ensure that current flows safely through the stranded wires. This helps to get rid of the heat that is created as current flows.

- Repetitive Motion: Stranded wires find their place in repetitive motion applications such as opening and closing doors. They are ideal for short distances and fit easily into patch cords.

- Reducing Skin Effect: In AC transmission and distribution lines, stranded wires may be chosen to minimise the skin effect.

Read Also - WHAT DO THE DIFFERENT COLOURS MEAN ON ELECTRICAL WIRES?

Disadvantages of Stranded Wire

- Corrosion Risk: Stranded wires may easily develop corrosion, especially in humid and outdoor areas.

- Lower Ampacity: The air gap between conductors in stranded wires results in a lower current-carrying capacity compared to solid wires of the same size.

- Higher Cost: Wires in a stranded configuration are usually more expensive than solid ones.

- Voltage Drop: The voltage drop in stranded wires can be higher, and they can produce noisy sound with an attenuation of 20-50% in high-frequency communications.

What is Solid Wire?

Solid wire refers to a single conductor encased in insulation. It is more massive and bulky than stranded wires. While there are some benefits of stranded wire, solid wire maintains its position, particularly in home wiring in the main panels and other uses.

Process of Manufacturing Solid Copper Wire

Initially, to manufacture solid copper wire, copper rods are drawn through a series of dies which decrease in size incrementally until the intended gauge for the specific application is attained. This stretching process makes the copper thinner and more fragile. After this annealing takes place, where the wire is heated up to improve its toughness and malleability. The wire is then made ready for use either as bare copper or insulated for various applications such as telecommunication, pet fences or tracer wire.

Advantages of Solid Wire

- Pure Termination: With solid wires, you have perfect termination and connection that result in an effective electric set-up.

- High Current Carrying Capacity: Solid wires can carry higher amounts of current than stranded wires with air gaps between conductors at equal gauge.

- Transparent Sound: Since there is less attenuation resulting in low noise levels, this makes these types of wires ideal for those applications that emphasize high-frequency transmission performance.

- Resistant And Durable: Resistance and corrosion properties give solid wire an upper hand over other types used indoors as well as outdoors.

- Less Voltage Drop: For long-distance purposes, solid wires have less voltage drop due to their lower resistance.

- Cost-Effective: Solid wires are usually cheaper than their stranded cousins.

Disadvantages of Solid Wire

- Less Flexibility: Solid wires are less pliable than stranded wires and therefore are not suitable for applications that require flexibility.

- Repetitive Motion Concerns: In repetitive motion applications the use of solid wires can result in cable damage.

- Skin Effect in High Voltage Lines: In high-voltage and power transmission lines, solid wires may have problems with skin effect.

- Not Suitable for Electronics: However, rigid wires may not be suitable for electronics, digital communication, and computer applications due to their inflexibility.

Difference between Stranded and Solid wire: Factors to Consider

When choosing between stranded and solid copper wire for a project, several important considerations should be done. However, every variant has its strengths and weaknesses, and the needs of the application are essential for making the right decision.

1. Strength

Naturally, solid copper is stronger than stranded copper due to the thicker conductor consisting of a single solid piece of metal. Unlike stranded copper, the latter is made up of several smaller cables twisted together, making it more pliable but relatively weaker.

2. Cost

Wire manufacturers prefer solid copper because its usage reduces the hassle in the wire manufacturing process. Stranded copper involves an extra step of twisting wires together, which increases the production time and cost.

3. Flexibility

Because solid wire is stiff and strong, it is appropriate for situations where flexibility is not a major factor. Stranded wire is very flexible, allowing easy routing and installation in confined spaces, and is therefore used in projects that require special flexibility.

4. Load Capacity

Even though both have the same gauge, solid wire has higher load capability and lower impedance than stranded wire because of the small surface area.

A stranded wire has greater surface area that results in a higher voltage drop along long runs, but the heat is dissipated efficiently due to air gaps formed during the twisting process.

5. Corrosion Resistance

Solid wire, on the whole, is more resistant to corrosion than stranded wire, as there are fewer areas where corrosion can set in. Wiith its many strands and air gaps, stranded wires are prone to corrosion. But conductors can be tinned to reduce this danger.

6. Applications

Solid cable is suitable for rough use, including sun-resistant insulation for outdoor use and direct burial applications such as tracer wires. For tight spaces and indoor environments, stranded copper is a better choice because of its flexibility and easy manipulation.

The decision between stranded and solid copper wire is based on the project requirements which may include strength, cost, flexibility, load capacity, resistance to corrosion, and the end-user.

Guide to Wire Selection: Key Considerations for Buyers

Buyers should consider a number of important factors when choosing wires to ensure maximum efficiency. Here are key areas to focus on when choosing different types of wires:

Voltage

Note the wire voltage carefully. The breakdown voltage of the insulation, as stated by the manufacturer after the tests, is of great importance. The cable drum usually provides this information. If the specification is higher than the system voltage, it is reasonable to use the wire.

Strength and Durability

The wire should be strong and durable. Cables used in mobile phones are usually small. Secondly, make sure that the cable insulation is resistant to different chemicals. For example, wires located in engine bays should be oil and fuel-resistant.

Ability to Handle Overheating

Assess the wire’s capacity to avoid overheating or jeopardising its insulation. Determine this capacity from the current running through the cable and its resistance, to represent the heat produced.

Size of the Wire

Choose a larger gauge wire as it is suggested by the professionals. This is especially important for low-voltage circuits. Emphasise the allowable voltage drop of the wire while a particular current flows through it. This is a general problem in low-voltage systems as compared to high-voltage systems.

Conclusion

The decision between stranded vs solid wire would be based on the specific needs of your project. Depending on whether you emphasise flexibility, strength, corrosion resistance or cost, knowing the properties of each type will help you make a good choice. Stranded wire has exceptional flexibility, making it a perfect choice for applications that involve frequent movement. Conversely, solid wire is known for its strength as well as its high ampacity and cost-effectiveness, which makes it a highly flexible option for a wide range of uses. So pick as per the application.

Read Also - HOW TO FIND THE SUITABLE SIZE OF CABLE & WIRE FOR ELECTRICAL WIRING INSTALLATION?

Comments