Understanding How PLCs and DCSs Differ in Industrial Control

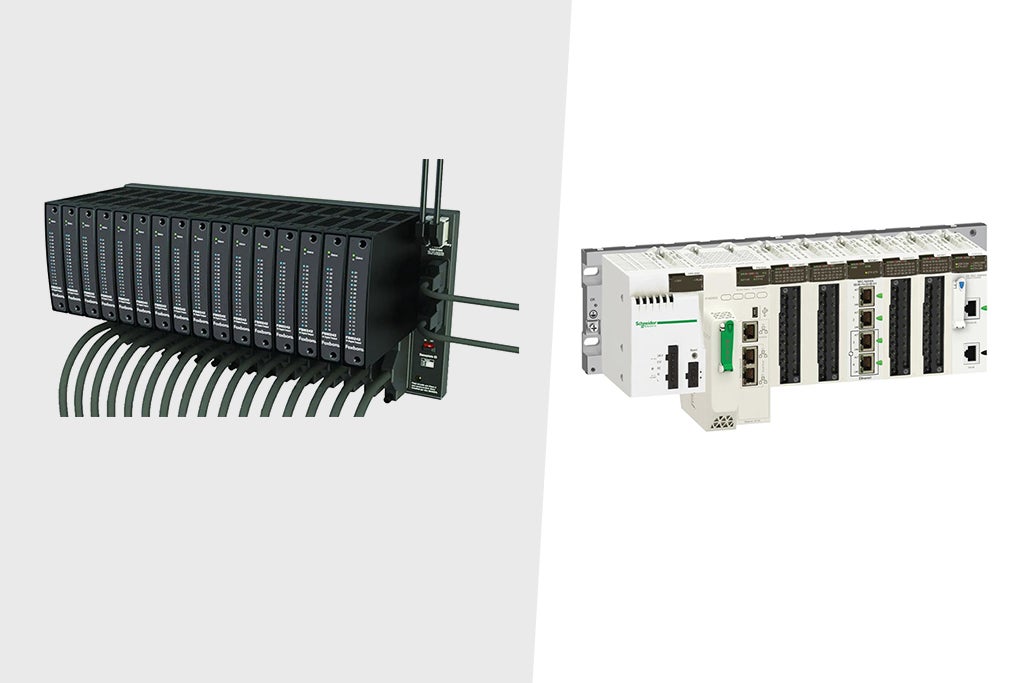

A frequently posed question in business management and automation systems pertains to the difference between Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS). Fundamentally, a PLC governs personal machines, whereas a DCS oversees the operation of a couple of devices within a manufacturing unit or plant. However, this is just a piece of basic information on PLC and DCS. Let us dig deeper into the PLC and DCS differences.

Understanding Programmable Logic Controller (PLC)

Definition of PLC

It is a complicated electronic tool broadly employed in commercial automation to control and streamline various strategies. Initially designed to replace conventional difficult-stressed relays, suitable judgment controllers, PLCs have emerged as indispensable to industrial settings, enhancing performance and precision. The number one cause of a PLC is to automate machinery and tactics by executing predefined good judgment based on input situations.

A standard PLC comprises five essential additives: a processing unit, memory unit, input-output interface, energy supply, and verbal exchange interface. The processing unit serves as the brain, executing programmed commands, while the reminiscence unit stores these instructions. The input-output interface connects the PLC to sensors and actuators, enabling it to acquire and enter statistics and send output signals.

History of Programmable Logic Controllers (PLC)

PLCs emerged as a replacement for antiquated manipulation systems reliant on relays and contactors. DCS, or distributed control systems, were created to meet the needs of the automation industry. They were not designed to replace PLCs but to coexist with them and improve plant or factory functionality.

The demand for PLCs arose because older systems lacked flexibility and took excessive time to repair problems. The outdated systems were complex to troubleshoot because of dirty connections, loose wires, and cryptic documentation. Control systems were still handled via relay controls, resulting in rooms covered in relays, terminal blocks, and cords.

In 1971, Allen-Bradley brought the Bulletin 1774 PLC a groundbreaking layout. Richard Morely is credited as the father of the PLC, as he played a pivotal role in its theory. Working with Modicon, Morely designed the authentic ladder programmable controller and pioneered ladder programming.

Understanding Distributed Control System (DCS)

Definition of DCS

A Distributed Control System (DCS) represents a more complete and decentralised approach to business manipulation. Unlike a PLC, a DCS is characterised by a network of manipulated additives disbursed for the duration of a plant or procedure. This nature eliminates the need for valuable operator supervisory manipulation, promoting a flexible and scalable system.

In a DCS, managing capabilities are localised near the applicable processes or flora, lowering setup costs and increasing device reliability. This structure additionally allows remote supervision and monitoring, facilitating seamless management of complex business processes. The significant components of A DCS consist of controllers, input-output (IO) modules, operator stations, engineering stations, and a storage and conversation machine.

DCS structures are in enormous packages throughout various industries, including petrochemicals, paper, energy technology, prescription drugs, refineries, and numerous production sectors. The scalability of DCS makes it especially suitable for procedures that require sizeable interplay among a couple of controllers.

Evolution of Distributed Control Systems (DCS)

The domain of process control began to grow rapidly in the early 1960s, mainly when Imperial Chemical Industries exchanged its analogue control system for a computer. With this change came the arrival of Direct Digital Control (DDC). In this revolutionary concept, a computer takes over the function of controlling a system, replacing the old analogue supervisory systems. DDC adoption would not only be more economical but also demonstrate greater efficiency. Therefore, numerous DDC languages appeared, with widespread use in temperature and ventilation control of building automation. This legacy is still seen today in Distributed Control Systems (DCS).

In the 1980s, technological advances focused mainly on computer replacement of the traditional analogue control system. Although bold, the following development involved setting up central systems that could unify the overall direction. Midac was one of the first companies to work in this area, creating its modern building automation system for the University of Melbourne. It was a system of microprocessors working together to divide and share work and memory.

With the ascendancy of Microsoft in the 1990s, we have seen a paradigm shift. Without the prospect of a continued hardware-oriented orientation, DCS companies saw the writing on the wall and decided to move towards software. Today, this trend demonstrates the evolution of the environment for process control, which is strongly influenced by software developments.

What is the difference between a Programmable Logic Controller (PLC) and a Distributed Control System (DCS)

The difference between PLC and DCS are as follows:

Definition and Structure

PLCs, abbreviated for Programmable Logic Controllers, are microcontrollers specially designed to automate industrial approaches. A normal PLC comprises five essential additives: a processing unit, reminiscence unit, enter-output interface, power delivery, and communication interface. On the opposite hand, DCS, or Distributed Control System, is a computerised device that utilises a couple of controllers dispensed for the duration of a plant for complete control and automation.

Objective and Type of Control

PLCs have mainly evolved to replace traditional tough-stressed relay controllers, eliminating the want for electromagnetic relays. PLCs excel in discrete management programs. Conversely, DCS is designed to replace single-loop controllers.

Redundancy and Architecture

While PLC redundancy won't continually be price-justified due to extra hardware prices, DCS inherently consists of redundancy as a default feature. PLCs have a straightforward and flexible architecture, at the same time as DCS structures exhibit a more complicated and much less flexible shape.

IO (Input-Output) Capacity and Response Speed

The IO handling potential of PLCs is low; normally, it handles some hundred IOs. In comparison, DCS systems boast higher IO handling capacities, frequently extending to many IOs. PLCs exhibit a quicker reaction time, generally in 1/10th of a second, whereas DCS structures have an exceptionally slower response time, around 30 ms.

Storage of Application Data and Number of Controls

PLCs store software facts in several databases, whereas DCS structures consolidate software records in an unmarried database. PLCs are constrained in the quantity of controls they can take care of, while DCS systems can correctly control a larger range of controls.

Processes and Predictability

For batch processing with minimum procedure interactions, PLCs make a perfect choice, while DCS structures excel in coping with interrelated, continuous, complicated approaches. The tactics of PLCs aren't completely predictable, while DCS strategies show off a higher degree of predictability.

Alerts and Cost Considerations

PLCs offer diagnostics to inform operators of malfunctions, while DCS structures alert operators to capacity troubles earlier than they arise. In terms of value, PLCs are frequently greater low priced in terms of hardware; however can also contain higher engineering costs. DCS hardware is relatively extra high priced, but the associated engineering costs are significantly decreased.

Size and Applications

PLCs are characterised by their compact length, making them suitable for numerous discrete production industries together with metallic, automobiles, and chemical compounds. In assessment, DCS structures are larger and discover their number one applications in manner industries, refineries, paper turbines, water management, remedy vegetation, and boiler controls.

Conclusion

The primary distinction between PLC (Programmable Logic Controller) and DCS (Distributed Control System) lies in their application focus: PLCs are mainly used in the process industry, while DCS is typical of discrete production industries. Nonetheless, despite this difference, both systems have the same primary function: control and automation.

High quality with low prices are the hallmarks of Schneider Electric electronic devices. If you want to find out for yourself, check out our eShop. What distinguishes Schneider Electric's eShop is that the devices listed here are technology-intensive yet simple. The complete system that Schneider Electric eShop offers to manage your electronic needs is even more comprehensive than the products.

Comments