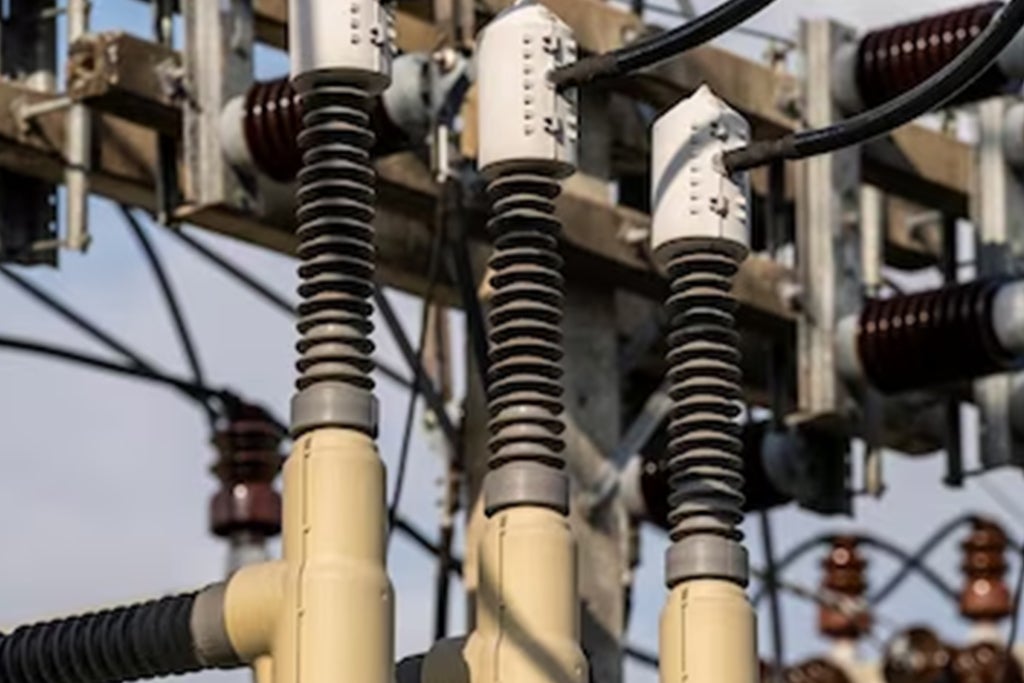

Types of Insulators Used in Power Transmission Lines

What is an Electrical Insulator

The electrical industry is a vast field with various innovations and inventions. Every invention is made to make the lives of humans easy and convenient. Amongst many others, one such is an electrical insulator. An electrical insulator is a material that impedes the flow of electric current. Its primary function is to resist or block the movement of electric charges, preventing the unintentional transfer of electricity between conductive materials. This property is crucial in various electrical systems and devices to ensure safety, reliability, and efficiency.

They are strategically placed to isolate conductive components, such as wires or electrical equipment, from one another and the surrounding environment. Insulators are essential in overhead power lines, electrical transformers, circuit breakers, and other electrical devices where maintaining a clear separation of conductive elements is critical. In addition to preventing electric shock hazards, insulators also play a crucial role in minimizing power losses by reducing leakage currents and ensuring the proper functioning of electrical systems. Their design and selection are tailored to withstand specific voltage levels and environmental conditions, making them integral components in the safe and efficient distribution of electrical power.

Different Types of Transmission Line Insulators

Let us look at the different types of insulators in transmission lines and their unique characteristics.

-

Pin Insulators

The most common type of insulator used in a transmission line, the pin insulator is typically used in smaller transmission lines and low-voltage distribution lines. Pin insulators comprise a single porcelain or glass body, with a threaded metal pin at the bottom to secure it to the cross-arm and other supporting structures.

Pin insulators are suitable for voltages up to 33kV and are preferred for their simplicity, easy installation, and cost-effectiveness. Their limited flashover voltage and mechanical strength, however, make them unsuitable for higher voltages.

-

Suspension Insulators

These transmission line insulators are mostly used in medium to high-voltage transmission lines. They are designed to support the conductors and insulate them from the supporting towers or structures. Suspension insulators consist of several units, usually made of porcelain, connected in series using metal links or rods.

A major advantage of suspension insulators is their ability to withstand higher voltages while providing robust mechanical strength. When multiple units are arranged in series, the overall flashover voltage also increases. Thus, the insulator can support voltages ranging from 33kV to several hundred kV.

-

Strain Insulators

This type of insulator used in a transmission line is also known as a tension insulator. Their principal utility is to absorb the tension in the conductors and keep them at a safe distance from supporting structures. Strain insulators are used in areas where tension in conductors is the highest— where transmission lines change direction or encounter dead-ends.

Strain insulators consist of a series of porcelain discs connected by metal links. This allows them to tackle both insulation and requirements of mechanical strength. These insulators typically find use in medium to high-voltage transmission lines.

-

Shackle Insulators

Also called spool insulators, they are used in situations where the transmission lines are required to change direction or pass through obstacles. They are connected directly to the supporting structures using metal shackles, providing a reliable and compact solution.

Shackle insulators are best suited to low and medium-voltage applications and are often used in distribution lines. They involve easy installation and maintenance because of their lightweight, making them cost-effective solutions in certain situations.

-

Post Insulators

These types of insulators in transmission lines are widely used in substations and stations where the conductors need to be insulated from the supporting structures. They consist of a single, solid porcelain or glass piece that is mounted on a metal base.

Post-insulators have excellent mechanical strength and high flashover voltage capability. They are commonly used in high voltage applications ranging from 11kV to several hundred kV.

-

Long Rod Insulators

These are designed to withstand mechanical and electrical stresses experienced by high-voltage transmission lines. They comprise a single long porcelain rod that provides a continuous path for current flow from the conductor to the tower.

Long rod insulators are popular for their superior mechanical strength and exceptional pollution performance. They are extensively used in extra-high voltage (EHV) and ultra-high voltage (UHV) transmission lines, where the environmental conditions are more challenging.

-

Stay Insulators

Also known as guy-wire insulators, these are used in transmission lines to provide insulation and mechanical support to the guy wires that stabilize the transmission towers. These insulators prevent the flow of current from the tower structure to the ground through the guy wires.

Stay insulators are typically constructed with porcelain and are designed to withstand both mechanical loads and electrical stresses. They are crucial for maintaining the stability and proper alignment of transmission towers, especially in areas with high wind loads or uneven terrain.

-

Spool Insulator

A spool insulator is a specialized type of electrical insulator commonly used in power distribution systems. Its design resembles a cylindrical or spool-like shape, which is where it gets its name. These insulators are typically made from materials such as porcelain or glass, chosen for their high resistivity and durability.

The main purpose of a spool insulator is to support and electrically isolate electrical conductors, such as wires or cables, from supporting structures like poles or towers. By providing a physical separation, spool insulators prevent the unintended flow of electrical current from the conductor to the supporting structure and vice versa. This is crucial for maintaining the integrity and safety of power distribution systems. These insulators are designed to withstand high voltage levels and harsh outdoor environments, making them essential components in the reliable and safe operation of electrical power grids.

Spool insulators are often used in overhead power transmission and distribution lines. They are mounted on cross arms, brackets, or other supporting structures to keep the conductors at a safe distance. The cylindrical shape of spool insulators helps distribute mechanical stresses evenly and ensures stability under various environmental conditions, such as wind, rain, and temperature fluctuations.

Overhead Line Insulators

Overhead line insulators are crucial components in electrical power transmission and distribution systems, designed to support and insulate conductors while preventing unintended current leakage. These insulators are specifically tailored for use in overhead lines, where electrical conductors are elevated on poles or towers to transmit power over long distances. They come in various designs, with common types including pin insulators, suspension insulators, and strain insulators, each serving specific purposes in the overhead line configuration.

Pin insulators are mounted on the cross arms of poles to support the conductors. Suspension insulators are used to hang conductors from the overhead structure, providing both electrical insulation and mechanical support. Strain insulators, on the other hand, are used to absorb and counteract the tension forces that may occur due to the weight and environmental conditions.

The primary function of overhead line insulators is to maintain a safe distance between the conductors and supporting structures, preventing electrical arcing or short circuits. They are designed to withstand the environmental challenges of outdoor exposure, including temperature variations, wind, rain, and pollution. Overhead line insulators play a crucial role in ensuring the reliability, efficiency, and safety of electricity transmission and distribution networks.

Pin Insulator vs Post Insulator

|

|

Pin Insulator |

Post Insulator |

|

Profile |

Small profile |

Large profile |

|

Design |

Designed to reduce stress on conductor |

Designed to provide more support for the conductor |

|

Placement |

Mounted on the cross-arm of pole of distribution lines |

Mostly installed to assume vertical positions |

|

Pins |

Have two or three pins |

Have four or more pins |

|

Price |

Cost effective |

Expensive and difficult to install |

|

Durability |

Longer lifespan |

Comparatively shorter lifespan |

|

Advantages |

Resistant to corrosion |

Resistant to environmental conditions |

Insulator properties

Insulators are materials with specific properties that make them effective in impeding the flow of electrical current. The key properties of insulators contribute to their role in maintaining electrical isolation and preventing unintentional electrical conduction:

- High Resistivity: Insulators possess high electrical resistivity, meaning they offer significant opposition to the flow of electric current. This property helps in blocking the movement of electrons and prevents the transmission of electrical energy through the material.

- Dielectric Strength: Dielectric strength is the maximum electric field a material can withstand without breaking down and allowing a current to flow. Insulators exhibit high dielectric strength, ensuring that they can endure the applied voltage without undergoing electrical breakdown.

- Mechanical Strength: Insulators must have sufficient mechanical strength to support the weight of conductors and withstand external forces such as wind, ice, and vibrations. This property ensures the structural integrity of insulators in various applications.

- Thermal Stability: Insulators need to maintain their properties over a range of temperatures. Thermal stability ensures that insulators can withstand the heat generated during electrical operation without undergoing significant changes in their physical or electrical characteristics.

- Chemical Inertness: Many insulators are designed to be chemically inert to resist corrosion or degradation when exposed to environmental factors such as moisture, pollutants, or chemicals.

These properties collectively enable insulators to perform their critical role in electrical systems by providing a barrier to the flow of electric current and ensuring the safety and reliability of the associated infrastructure.

Also Read: Control Relays - How They Work & What They Are For?

FAQs

Q1. What is an insulator used for power lines?

Insulators used in power lines are typically made of materials like porcelain, glass, or composites. These insulators are designed to prevent the unintended flow of electricity between the conductive components of the power lines and the supporting structures, such as poles or towers. By offering high electrical resistivity, mechanical strength, and resistance to environmental factors, these insulators maintain the necessary electrical isolation, ensuring the safe and efficient transmission of power over long distances in overhead lines.

Q2. How many insulators per kV?

The number of insulators per kilovolt (kV) in a power transmission or distribution system depends on factors such as the voltage level, type of insulator, and the design of the overhead line. Generally, higher voltage levels require more insulators to ensure effective electrical isolation. For instance, higher voltage lines may use insulator strings, which consist of multiple insulators connected in series. The specific configuration and number of insulators per kV vary based on engineering considerations and standards applicable to the particular power system.Q3. What are the 4 best insulators?

The four best insulators commonly used in electrical applications are:

- Glass: Glass insulators are known for their high resistance to electrical conductivity and durability.

- Porcelain: Porcelain insulators exhibit excellent electrical insulating properties and mechanical strength, making them suitable for various voltage levels.

- Ceramics: Ceramics, including advanced composite materials, are chosen for their high resistance and ability to withstand harsh environmental conditions.

- Rubber: Rubber insulators are flexible and provide good electrical insulation, often used in applications where flexibility is required, such as in some types of cables and connectors.

Comments