5 Essential Maintenance and Troubleshooting Tips for VFDs!

A Variable Frequency Drive, commonly called a VFD, is a motor controller. The primary function of this controller is to drive an electric motor by varying the power supply's voltage and frequency. These controllers also have the power to control ramp-up during the start and ramp-down during the stop of the motor.

The contribution of VFD is unparalleled in the manufacturing industry to maximise productivity and efficiency. However, they might falter at times and fail to function to their full potential. To prevent such situations, it is essential to follow some essential VFD maintenance steps.

This post will introduce you to the five most essential maintenance tips of VFDs and also five VFD drives troubleshooting tips. So, start reading below.

Also Read: Variable Frequency Drives - Everything You Need To Know About VFDs

VFD Maintenance Tips

To maximise the life expectancy of a VFD, it is essential to maintain its condition well. Below are the five most essential VFD maintenance tips that must be followed to ensure smooth operations.

Regular Cleaning

One of the most prominent maintenance tips for this controller is that you must keep them clean. Industrial and commercial areas have a lot of airborne dust and debris that might accumulate over a VFD and negatively impact its functioning. To avoid this, regardless of the VFD chassis type, regular cleaning must be ensured for VFD. Its heat sink and fans must be kept clean always. Periodic cleaning of VFDs can be done through wiping, cleaning and air spraying the accumulation from them.

Temperature Maintenance

Another crucial tip that must be followed for top-notch maintenance of VFDs is that their temperature must be maintained, as these are mostly used in compact areas where heat spikes are a common thing. However, to maintain their optimum temperature, appropriate air circulation must be ensured. Also, temperature control systems must be installed.

Regular Visual Inspections

Another proactive approach for the maintenance of VFDs is regular visual inspections. Maintenance personnel with a basic knowledge of these controllers must inspect them visually weekly to identify any visible faults. Some of the key inspections that must be looked after include the working of area cooling systems, fibre optic cables, connections and emergency circuits.

Prevent Moisture Penetration

Water and electricity is not a suitable combination in any industrial setting and it is no different with the Variable Frequency Drives. VFDs must not come in contact with moisture as it will inevitably cause various problems like equipment failures, erratic behaviours and corrosion. Therefore, VFDs must be kept dry.

Intact Connections

Next on the list of VFD maintenance tips is that you must ensure tight connections. The electrical connections might have loosed up due to the constant vibrations. Loose connections will result in uneven operations of the controller. Therefore, the maintenance personnel should regularly check the connections.

As you are now equipped with the best maintenance tips for VFDs, move on to the next section of this post that will serve you as a VFD troubleshooting guide.

VFD Drives Troubleshooting

Even after following all the maintenance tips regularly, breakdowns might occur, as is the reality of the industry. Several reasons can cause these breakdowns and disturb the operation of your business. However, there are some simple troubleshooting ways, as listed below, that can be tried before calling in help from a Variable Frequency Drive repair provider.

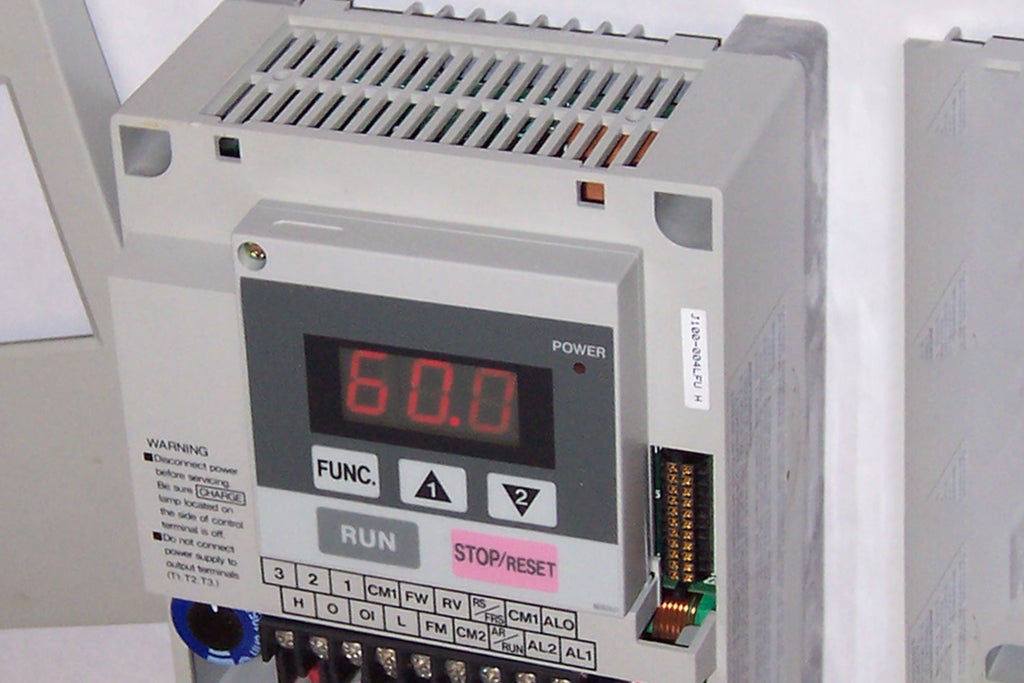

Check Diagnostics Display

The advanced VFDs by the best manufacturers come with built-in troubleshooting functions. If your VFD has a display module, check it to see if it indicates any issues like irregular voltage, overheating or a popped fuse. Most small issues with these controllers can be solved with this.

Check for Moisture

Another effective tip in this VFD troubleshooting guide is that if you are facing an issue with this drive, conduct a visual inspection to look for a moisture inspection. It is important to note that you must not touch the machinery and just take a look at it for moisture. Water can cause shorts and other issues that might have resulted in inefficient working. To remove the water accumulation, take safety precautions first and do not touch the wet electrical equipment.

Check for Dust

Another VFD drive troubleshooting tip is to ensure that the VFD is clean from dust and debris. The dirty industrial and commercial environment usually results in grit accumulation inside the VFDs that cause their malfunction. You must inspect it for dust accumulation and remove it from the electric motor to clean it. While cleaning is being done another VFD can be used in its place. After cleaning, it can be reinstalled, and the backup option can be stored back.

Check VFD Connections

You must also check for the VFD connections to see if they are tight enough. However, before you check this, it is essential to wear all the safety equipment. Now, check the connections visually and physically for loose connections.

Resonance Testing

The vibrations caused while working on equipment cause undue stress on it that impacts welds, loosens bolts and causes various other damages. You can run a diagnostic test to check if the VFD is excited due to resonance.

Read Also - What's The Difference Between A Soft Starter And A VFD?

Conclusion

Following the right maintenance and troubleshooting tips can be quite helpful in keeping the operations up and running. You can also follow the VFD troubleshooting flowchart. If you are looking for the most high-quality Variable Frequency Drives, there is no better brand than Schneider Electric. You can shop online from us at our online store- https://eshop.se.com/in/.

Frequently Asked Questions

Q1. How can VFD failure be prevented?

Ans: You can regularly practise certain maintenance tips to prevent VFD failure like prevention of moisture, dust and debris accumulation.

Q2. What is the main cause of VFD failure?

Ans: Usually, VFD failures are a result of bad environmental conditions like high temperatures, moisture, dust and debris.

Q3. What are the maintenance steps for VFD?

Ans: VFD maintenance involves several steps that must be followed regularly to ensure smooth operation, like regular removal of dust and debris, checking and removing moisture accumulations, ensuring tight VFD connections and temperature maintenance.

Comments